jarolla ka ho iketsa bolo jere ABB dilenaneo khalase edging bentsa mochini

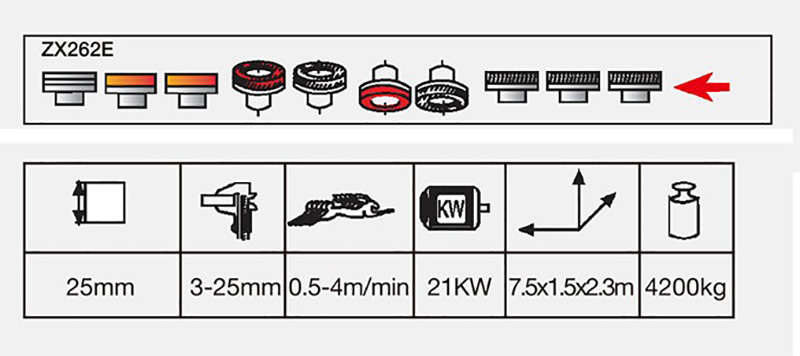

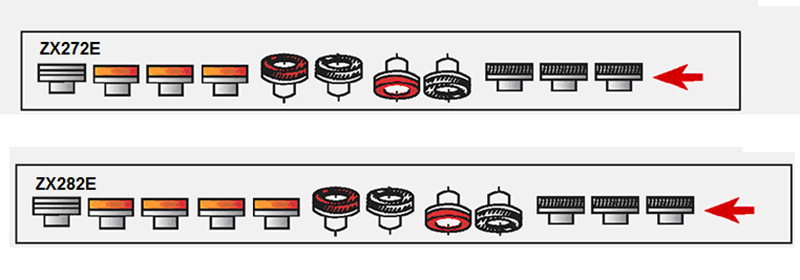

ZX262E / ZX272E / ZX282E

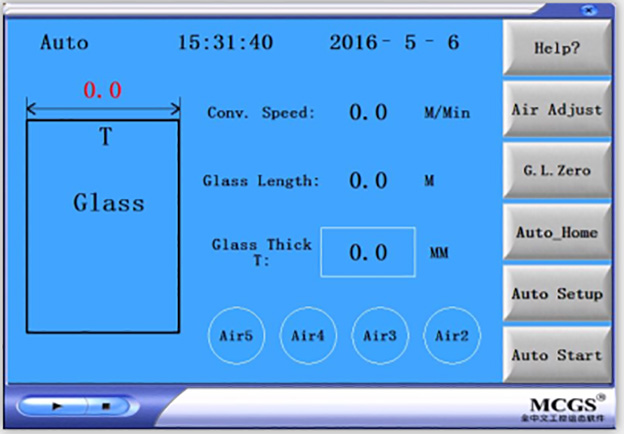

Sistimi e sebetsang ea taolo ea "Mitsubishi PLC" le "touch panel"

Sebopeho se nang le bolo e phahameng haholo, ts'ebetso e tsitsitseng le ts'ebetso e ntle ea metsi

Conveyor ea morao e na le borashe bo hloekisang, boo, bo bolokang bokaholimo bo hloekileng le netefatso ea sephetho sa tšebetso

sistimi ea setlolo

Sesebelisoa sa metsi a se nang tšepe se potoloha

Selelekela sa Mochini

a) Sisteme ea taolo:

Mochini ona o sebelisa sistimi e sebelisang taolo ea PLC le touch. Mochini o ka sebetsa ka mokhoa o iketsang le ka mokhoa oa matsoho.

b) Ho tsamaisa:

Conveyor amohela chainless phikolosetsa tsamaiso e khopo ho fetisa, e nang le dibering tharo phethola hammoho tataisa phahameng sebetsa ka ho nepahetseng tšepe, motsamao oa khalase o tsitsitse haholo.

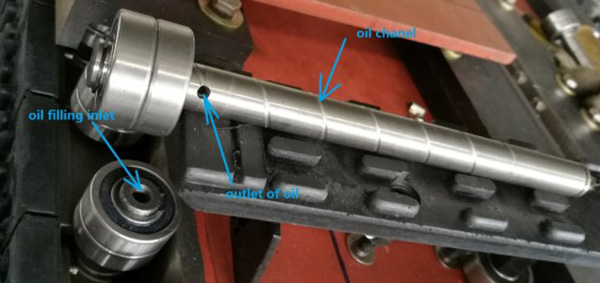

Libering tsa motlakase tse tsamaisang ka pele le ka morao li tlotsitsoe ka bo eona ke pompo ea oli, tsela e entsoeng hantle ea oli e nolofalletsa libering tse holimo le tse tlase ho fumana oli ka ho lekana.

Conveyor ea morao e na le borashe bo hloekisang, boo, bo bolokang bokaholimo bo hloekileng le netefatso ea sephetho sa tšebetso.

c) Mochini o na le ts'ireletso ea khalase ea botenya. Ha khalase ea botenya e fosahetseng e kenngoa mochining. Mochini o tla emisa ka bohona. Sena se sireletsa libering hore li se ke tsa sithabetsoa.

d) Ho lata / ho tima lebanta la tšebeliso ea nako ea ho tsamaisa. E ka fetola bophahamo ho beha likhalase tse fapaneng tse tlositsoeng.

e) Khalase ea tšehetso e sebelisa khalase ea Aluminium extrusion, e nang le roller roller.

f) Sekoahelo se tsamaisang thepa se entsoe ka tšepe e sa hloekang.

g) Motsamao oa pele oa ho tsamaisa o tsamaisoa ka enjene. E ka fetoloa ka konopo ea motlakase ho karolo e sebetsang kapa e fetoha ka bo eona. Botenya bo bonts'oa skrineng. Ho boetse ho na le 'malatsi oa ho bala o bonts'a botenya ba khalase.

h) Phetoho ea lebelo la ho sebetsa:

Sebetsa lebelo ke fetolehang ka maqhubu inverter.

i) Li-spindle li khannoa ke li-motor tsa ABB tsa boleng bo holimo.

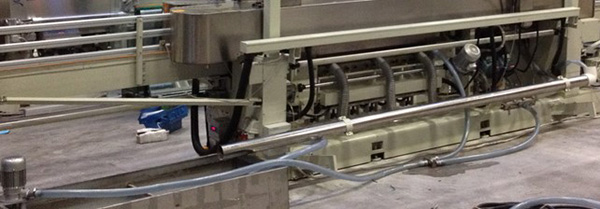

j) Sisteme ea metsi

Metsi a potoloha mochining le tanka ea metsi e sa hloekang. Pipe ea tšepe e sa hloekang e kentsoe ka morao mochini ho tsoa metsi ka tankeng ea mabili. Metsi a hloekileng a pompeloa mochining ka har'a tube ea metsi e sekwere. Ho kenya sistimi ea ho tsamaisa metsi ho bonolo haholo.

Litekanyetso tsa tekheniki

| Ntho | Paramente | Boholo |

| 1 | Lisebelisoa: | Lihlooho tse 9. |

| 2 | sebetsa Lebelo: | 0.1m-3.8m / mets |

| 3 | Ho sila botebo: | 3mm |

| 4 | Boholo. bophara ba arris: | 2.5mm |

| 5 | Khalase botenya: | 3mm-30mm |

| 6 | Min. khalase size: | 25mmX25mmX8mm |

| 7 | Kakaretso ea Matla: | EA-19.85kw |

| 8 | Ka kakaretso teba: | 8.0mx1.2mx2.0m |

| 9 | Kakaretso ea Boima: | 5700kg |