habeli edger a bataletseng edgers feletseng jarolla ka ho iketsa

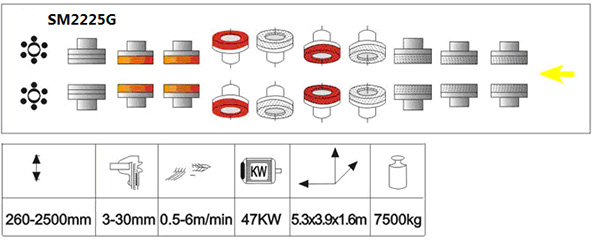

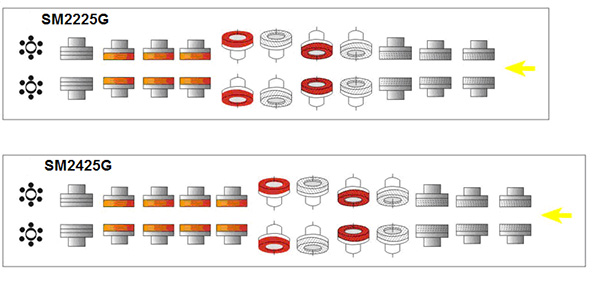

SM2025G

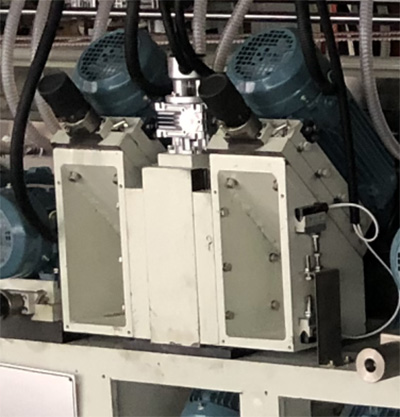

Sesebelisoa sa bolo le mafahla a tsamaiso ea mafahla bakeng sa phetoho ea bophara

Sistimi e kaholimo ea pina le enjene e holimo ea arris

Sistimi ea ho khanna

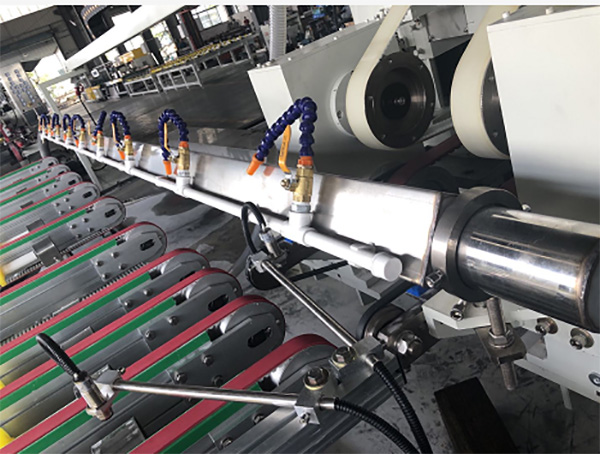

Likoloi tsa pneumatic polshing

Lehare le omileng la moea le nozzle ea ho fafatsa metsi

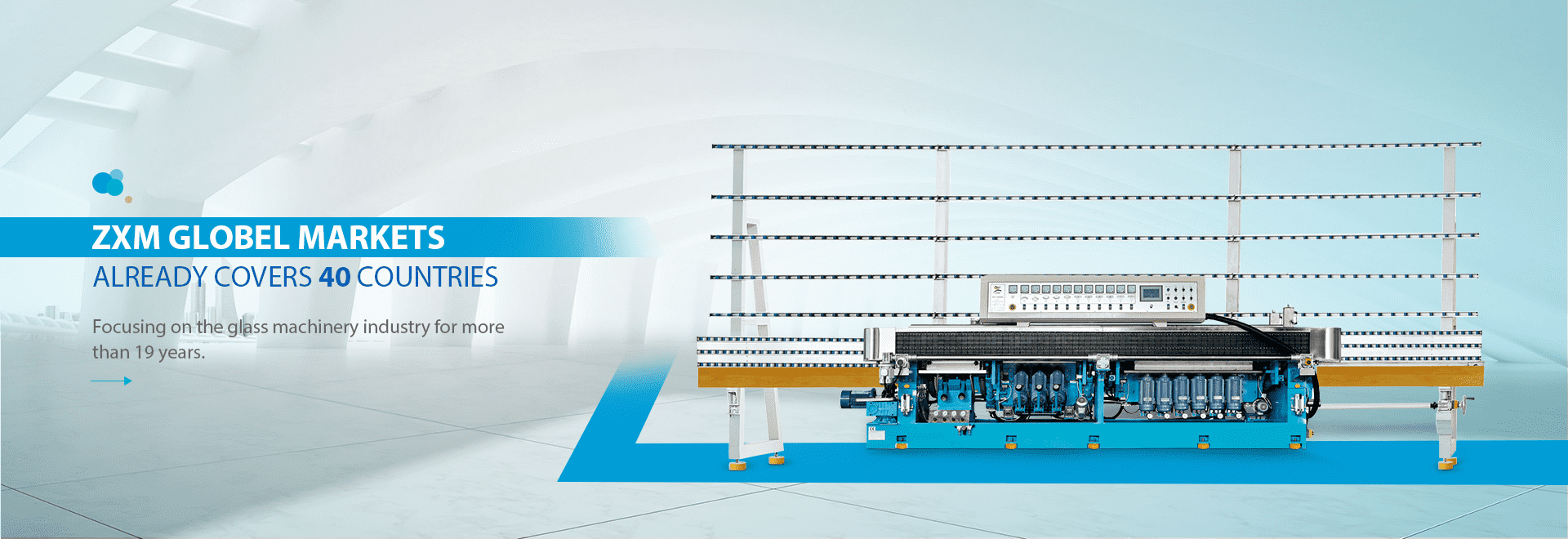

Selelekela sa Mochini

Mochini ona o etselitsoe ho bentsa likarolo tse peli tse fapaneng tsa khalase ka nako e le 'ngoe.

a) Taolo

Mochini ona o amohela taolo ea Japane ea Mitsubishi PLC le sehokelo sa opareitara sa 8 ”. Screen e bonts'a likarolo tsohle tse hlakileng tsa khalase. Mochini o mong le o mong o ka laoloa ke komporo ea ona kapa oa laoloa ke komporo e kholo. Tokelo ea mosebelisi e ka hlophisoa hore e be opareitara / tokiso / motsamaisi, ho thibela phoso ho etsahala, ho sireletsa mochini ho sebelisaneng hampe.

b) Phetiso e phahameng haholo.

Mabanta a mabeli a tsamaisang nako a tsamaisoa ke makoloi a fapaneng a Frequency, a nang le tšobotsi ea ho nepahala ho phahameng, lebelo le phahameng.

c) Tsamaiso ea ho sila ea mobile.

Karolo ea mochini oa mochini o tsamaeang o tsamaisana le motataisi o tsamaisang mafahla a bolo. Phetiso e kenngwa tshebetsong ka woman stage bolo, e leng khannoang ke dilenaneo le Brake, le Max fallela lebelo la karolo sila ka fihla 8 mitha ka motsotso. Sistimi ena e kenyelletsa le brake le gripping system, e ka netefatsang ho sisinyeha ho tsitsitseng ha karolo e silang, matla a tlase a tšusumetso. Sebopeho sena se ka tiisa botsitso ba matla a ts'oarang khalase e kholo, le kamora mochini o sebetsang nako e telele.

d) Edger e na le seporo se le seng sa ts'ehetso se tsamaeang, se ka behoang bohareng ba lipalangoang tse peli ho ts'ehetsa khalase ho tloha boemong bo bohareng ho thibela khalase hore e kobe.

e) Tsamaiso e holimo le e tlase ea ts'ebeliso ea poleiti ntle le bothata bo tiileng ba sistimi ea setso e thellisang.

f) Sisteme ea boemo.

Khalase e jarang boemo ba sistimi e kenyelletsa likarolo tse 'ne: li-roller tse sa fetoheng, sistimi e tsamaisang moea e tsamaisang moea, ho hokahanya li-block (e le' ngoe ho le letšehali le e 'ngoe ka ho le letona), li-roller tse holimo tse hatellang moea (le leng ho le letšehali le le leng le letona). Khalase e hokahantsoe hantle ebile e petelitsoe ka thata ke sistimi ea boemo. Sisteme ena e tiisa tšebetso ea ho sila le polishing.

g) Phetoho e bonolo

Ho phahamisa / ho theoha ha sistimi e holimo ea ho latedisa le li-motor tsa arris tse holimo li tsamaisoa ke likoloi. E ka ipehela ka tsela e iketsang ho latela botenya bo fapaneng ba khalase.

h) Sistimi e bentšang moea.

Lebili le bentšang le sebelisoa ke moea, o laoloang ke PLC le motlakase oa motlakase, o ka fetelang pele / morao ho latela boemo ba khalase. Sisteme ena e ka busetsa mabili a khathollang, e fana ka khatello e tšoanang ho khalase le ho fumana sephetho se tšoanang sa polishing.

Sistimi e tsamaisang makoloi e tsamaisang e sebelisa sistimi e phahameng ea literene e tsamaeang hantle.

i) Kamore e ka tlase le foreimi: Li entsoe ka tšepe e teteaneng e entsoeng, e alafshoang ka sebopi sa annealing fekthering ea rona. Ka botsitso bo botle le matla a khahlanong le torsional, matla a khahlanong le ho khumama.

j) Likoloi

Sebelisa phahameng sebetsa ka ho nepahetseng, le tlaase thothometsa ABB dilenaneo.

Sisteme ea taolo ea makoloi e na le ts'ireletso ea ts'ebetso ea overload / tlhokeho mohato / potoloho e khuts'oane, likarolo tsa elektroniki li sebelisa mofuta oa machabeng, mefuta e tloaelehileng, e ka fumaneha habonolo 'marakeng, e fokotsang litšenyehelo tsa tlhokomelo ea moreki, e eketsa ts'ebetso ea tlhahiso.

k) Top / Bottom fetisang conveyor amohela mabanta a nako.

l) Ho tlotsa: Mafahla a bolo e nang le sekontiri se sephara le seporo sa motataisi li lubricated ke pompo ea oli e iketsang. Mochini o boetse o na le pompo ea litlolo ea letsoho, e tlotsang bokaholimo bo thellisang ..

m) Phetoho ea lebelo la ho sebetsa: Ka maqhubu inverter.

n) Tanka ea metsi, terei ea metsi, sekoahelo sa lebanta se holimo / tlase sa nako, sekoaelo sa seporo / sekoaelo sa bolo se entsoe ka tšepe e sa hloekang.

o) Metara ea Amperometer: hlahloba khatello ea lebili.

Litekanyetso tsa tekheniki

|

Ntho |

Paramente | Boholo |

|

1 |

Lisebelisoa: |

Lihlooho tse 20. |

|

2 |

Min. khalase bophara: |

260mm |

|

3 |

Boholo. khalase bophara: |

2500mm |

|

4 |

Khalase botenya: |

3mm-30mm |

|

5 |

Sebetsa Lebelo: |

0. 5m-7m / mets |

|

6 |

Lebelo la phetoho ea bophara |

0-10000 limilimithara / mets |

|

7 |

Kakaretso ea matla: |

50KW |

|

8 |

Ho sebetsa khatello ea moea |

0,15 ~ 0.8MPa |

|

9 |

Karolo ea kantle |

5301 × 4421 × 1606 limilimithara |