habeli edging line high speed super glass finish T ea ho fetisa tafole

FH4225 SM2242GT + ZT4225 + SM2225GTS

Laola komporo

Sisteme e nepahetseng ea ho lekanya servo

bophara phetoho tsamaiso

Boleng bo phahameng likarolo tsa elektronike

Pneumatici bentsa tsamaiso

Enjene ea Arris

Tafole e phahameng ea phetisetso

Tafole e phahameng ea phetisetso

Selelekela sa Mochini

Tafole ea ho lekanya khalase

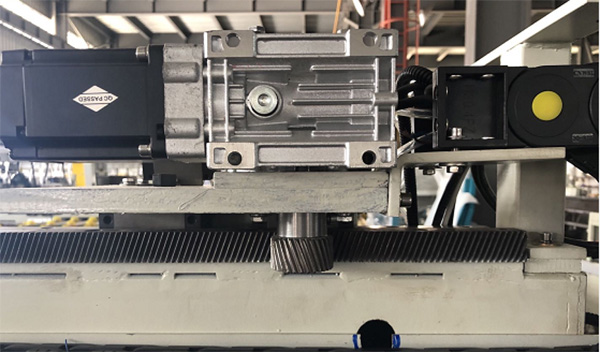

Tsamaiso ea ho khanna

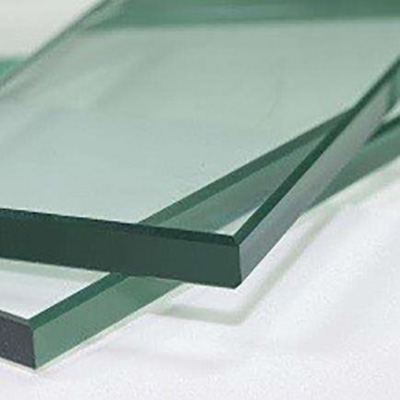

Lisebelisoa li sebelisetsoa ho fetisetsa le ho beha khalase hore e sebetsoe, ho etsa litekanyo tse nepahetseng tsa bolelele, bophara le botenya ba khalase, ebe li fetisetsa data ho grinder e habeli le lisebelisoa tse ling tsa ho e lokisa bakeng sa ts'ebetso e ngoe ea khalase.

Kaho ea tafole ea ho lekanya khalase e kenyelletsa likarolo tse 4 ka tlase:

1. Tafole ea Positiong

Phetiso ea khalase e fetelang pele kapa lehlakoreng e tsamaisoa ke maqhubu a converter le polygonal maqhubu dilenaneo. Lebelo la phetiso le ka fetoloa. Boemo bo nepahetseng ka lisele tsa boleng bo holimo. Bolelele, bophara le botenya ba khalase li ka lekanyetsoa kamora ho beha hantle.

2. Ho lekanya sesebelisoa

Bophahamo ba bolelele ba khalase le bophara bo lekanyetsoa ke sensor ea "drive drive" e nepahetseng haholo e khannoa ke servo motor. Bophahamo ba botenya ba khalase bo lekanyetsoa ka khatello ea silindara e khannoang ka holim'a khalase le kh'outeng e khannoang ke lisebelisoa. Khatello ea silindara e fetoloa ka thoko.

3. Sisteme ea taolo ea motlakase

ECS e na le li-programmable controller (PLC), touch screen (HMI), servo driver, servo motor, frequency converter, frequency frequency motor, sensor, jj. PLC e laola mochini hore o sebetse ka boiketsetso ho latela theknoloji ea ts'ebetso. HMI e phethela mosebetsi oa tšebelisano ea batho le likhomphutha.

4. Lenaneo la software

Sistimi ea software e bapisa data ho tsoa tafoleng ea ho lekanya khalase le data ea odara, 'me e ipapisa le data e haufi ea khalase. Khabareng, data ea khalase e fetisetsoa ho grinder e habeli ea bohale le lisebelisoa tse ling tsa ts'ebetso bakeng sa tlhahiso ea "mode" kapa "batch".

Khosana e sebetsang:

Ka letsoho kapa ka boiketsetso beha lakane e le 'ngoe ea khalase tafoleng e lekanyang khalase. Tafole ea ho lekanya khalase e fetisa, boemo le ho lekanya ka nepo litekanyo tsa bolelele ba khalase, bophara le botenya. Boitsebiso bo lekantsoeng ba khalase bo fetisetsoa tsamaisong ea tsamaiso ho bapisa ho bapisa data ea odara ebe bo fetisetsoa ho grinder e habeli ea bohale le lisebelisoa tse ling tsa ho e lokisa bakeng sa ts'ebetso ea khalase ea kamoso. Letlapa le le leng la khalase le latelang le beoa tafoleng ea ho lekanya khalase ebe le qala potoloho e latelang ea ts'ebetso.

2. Khalase e otlolohileng mochini o habeli oa polishing mochini.

Setšoantšo sa No .: SM2242GT SM2225GTS

Mochini ona o etselitsoe ho bentsa likarolo tse peli tse fapaneng tsa khalase ka nako e le 'ngoe.

a) Taolo

Mochini ona o amohela taolo ea Japane Mitsubishi PLC le 10 "interface interface. Screen e bonts'a likarolo tsohle tse hlakileng tsa khalase. Mochini o mong le o mong o ka laoloa ke komporo ea ona kapa oa laoloa ke komporo e kholo.

Tokelo ea mosebelisi e ka hlophisoa hore e be opareitara / tokiso / motsamaisi, ho thibela phoso ho etsahala, ho sireletsa mochini ho sebelisaneng hampe.

b) Phetiso e phahameng haholo.

Mabanta a mabeli a tsamaisang nako a tsamaisoa ke likoloi tse peli tsa servo, tse nang le tšobotsi e nepahetseng haholo, lebelo le phahameng.

c) Tsamaiso ea ho sila ea mobile.

Karolo ea mochini oa mochini o tsamaeang o tsamaisana le motataisi o tsamaisang mafahla a bolo. Phetiso e kenngwa tshebetsong ka woman stage bolo, e leng khannoang ke servo dilenaneo, le Max fallela lebelo la karolo sila ka fihla 15 mitha ka motsotso. Sistimi ena e kenyelletsa le brake le gripping system, e ka netefatsang ho sisinyeha ho tsitsitseng ha karolo e silang, matla a tlase a tšusumetso. Sebopeho sena se ka tiisa botsitso ba matla a ts'oarang khalase e kholo, le kamora mochini o sebetsang nako e telele.

d) Edger e 'ngoe le e' ngoe e habeli e na le seporo se le seng sa tšehetso ea bohareng ba autoamtic, se tsamaeang le karolo ea grinidng e tsamaeang, e tšehetsang khalase ho tloha maemong a bohareng ho thibela khalase hore e se kobehe. Bakeng sa edger e boholo bo boholo haholo, re boetse re fana ka seporo se le seng sa tšehetso se nkehang habonolo, se ka behoang ka letsoho ha se hlokahala.

e) Tsamaiso e holimo le e tlase ea ts'ebeliso ea poleiti ntle le bothata bo tiileng ba sistimi ea setso e thellisang

f) Sisteme ea boemo.

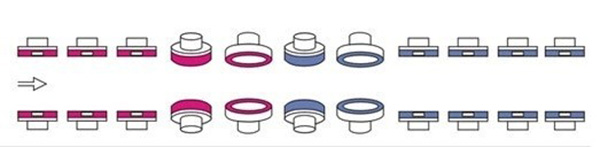

Khalase e jarang boemo ba sistimi e kenyelletsa likarolo tse 'ne: li-roller tse sa fetoheng, sistimi e tsamaisang moea e tsamaisang moea, ho hokahanya li-block (e le' ngoe ho le letšehali le e 'ngoe ka ho le letona), li-roller tse holimo tse hatellang moea (le leng ho le letšehali le le leng le letona). Khalase e hokahantsoe hantle ebile e petelitsoe ka thata ke sistimi ea boemo. Sisteme ena e tiisa tšebetso ea ho sila le polishing.

g) Phetoho e bonolo

Ho phahamisa / ho theoha ha sistimi e holimo ea ho latedisa le li-motor tsa arris tse holimo li tsamaisoa ke likoloi. E ka ipehela ka tsela e iketsang ho latela botenya bo fapaneng ba khalase.

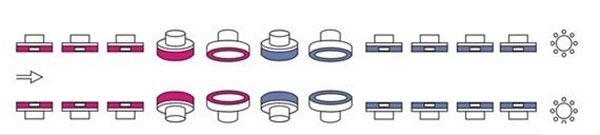

h) Sistimi e bentšang moea.

Lebili le bentšang le sebelisoa ke moea, o laoloang ke PLC le motlakase oa motlakase, o ka fetelang pele / morao ho latela boemo ba khalase. Sisteme ena e ka busetsa mabili a khathollang, e fana ka khatello e tšoanang ho khalase le ho fumana sephetho se tšoanang sa polishing.

Sistimi e tsamaisang makoloi e tsamaisang e sebelisa sistimi e phahameng ea literene e tsamaeang hantle.

i) Kamore e ka tlase le foreimi:

Li entsoe ka tšepe e teteaneng e entsoeng, e alafshoang ka sebopi sa annealing fekthering ea rona. Ka botsitso bo botle le matla a khahlanong le torsional, matla a khahlanong le ho khumama.

j) Likoloi

Sebelisa phahameng sebetsa ka ho nepahetseng, le tlaase thothometsa ABB polygonal maqhubu dilenaneo. Lebelo la likoloi le ka eketsoa ho 4300RPM ka li-inverter tsa maqhubu, lebelo la ts'ebetso ea mochini le ka eketsoa ho 20 metara / motsotso.

Sisteme ea taolo ea makoloi e na le ts'ireletso ea ts'ebetso ea overload / tlhokeho mohato / potoloho e khuts'oane, likarolo tsa elektroniki li sebelisa mofuta oa machabeng, mefuta e tloaelehileng, e ka fumaneha habonolo 'marakeng, e fokotsang litšenyehelo tsa tlhokomelo ea moreki, e eketsa ts'ebetso ea tlhahiso.

k) Top / Bottom fetisang conveyor amohela mabanta a nako.

l) Ho tlotsa:

Mafahla a bolo e nang le sekontiri se sephara le seporo sa motataisi li lubricated ke pompo ea oli e iketsang.

Mochini o boetse o na le pompo ea litlolo ea letsoho, e tlotsang bokaholimo bo thellisang.

m) Phetoho ea lebelo la ho sebetsa: Ka maqhubu inverter.

n) Tanka ea metsi, terei ea metsi, sekoahelo sa lebanta se holimo / tlase sa nako, sekoaelo sa seporo / sekoaelo sa bolo se entsoe ka tšepe e sa hloekang.

o) Metara ea Amperometer:

lekola boits'oaro ba lebili.

Lintlha tse ling lifoto.

Sekhutlo se sehiloe mochini o silang

Moralo oa module oa khokahano o sa keneleng metsi o kenang sebakeng se seng sesupo se utloisisehang sa ampermeter ea li-arris tsa hodimo le tlase.

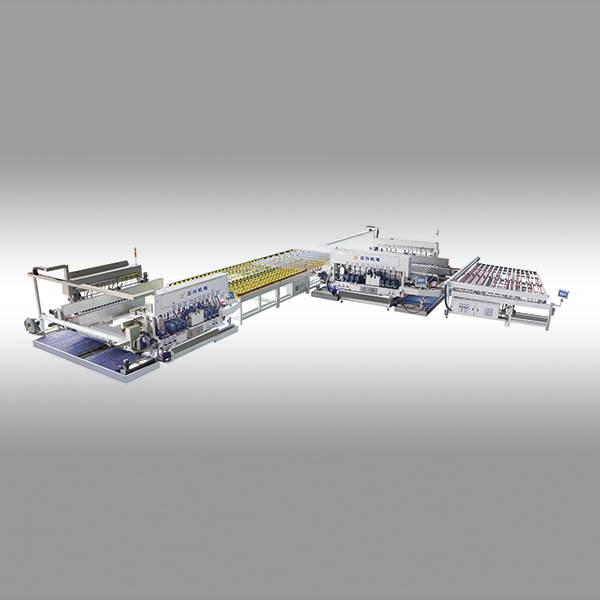

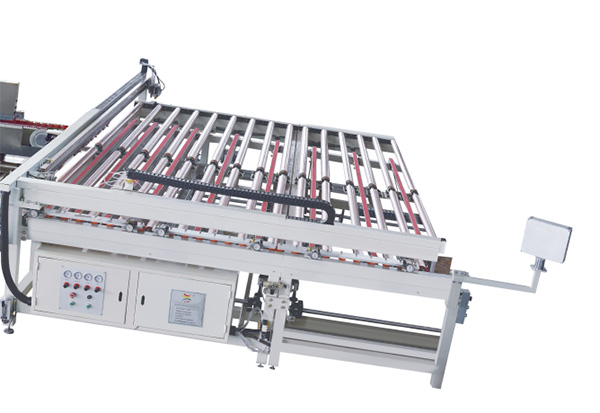

3. L- sebopeho Tafole ea phetiso. Tafole ea roller le lebanta la nako.

Mochini ona o entsoe ka sistimi e fetisang ea roller le tsamaiso ea nako ea lebanta e fetisang. Sisteme e fetisang ea roller e tsamaisoa ke ketane, lebelo le thibetsoe ke inverter e khutsufatsang lebelo la ho beha.

Nako ea ho tsamaisa lebanta e ka phahamisa le ho theoha tlase. Ha khalase e tsoa ho edger ea pele e 'meli, sistimi ea lebanta la nako e tla phahamisoa. Khalase e tla fallisetsoa positon e nepahetseng ebe e theoleloa tlase tsamaisong ea phetiso ea roller.

Sistimi ea conveyor lebanta e sebelisa 'mele oa aluminium.

Litekanyetso tsa tekheniki

Lebelo la tlhahiso

| Ntho | Botenya ba khalase | Boholo. sebetsa ka lebelo | Khalase e Felile |

|

1 |

4 - 6 limilimithara | 22 m / mets | Ho sila ka thata |

|

2 |

8 -10 limilimithara | 18 m / mets | Ho sila ka thata |

|

3 |

12 - 15 limilimithara | 15 m / mets | Ho sila ka thata |

|

4 |

4 - 6 limilimithara | 16 m / mets | E ntle bentsa |

|

5 |

8 -10 limilimithara | 14 m / mets | E ntle bentsa |

|

6 |

12 - 15 limilimithara | 12 m / mets | E ntle bentsa |

Sebetsa sebetsa ka ho nepahetseng:

| Ntho | Tlhaloso | Sebetsa ka ho nepahetseng Boholo |

|

1 |

Ho nepahala ha mola oa diagonal | ≤0.5mm / limithara |

|

2 |

Sebetsa ka ho nepahetseng e tšoanang | ≤0.2mm / limithara |

|

3 |

Ho nepahala ha boholo ba Arris | ≤0.2mm / limithara |

|

Ntho |

Paramente | Boholo |

|

1 |

Boholo. boholo ba khalase | 4200x2500 limilimithara |

|

2 |

Min. boholo ba khalase | 350 x 350 mm, singe edger habeli ntle le bracket e bohareng400 x 400 mm, mola kaofela) |

|

3 |

Botenya ba khalase | 3 - 28 limilimithara |

|

4 |

Bophara ba Arris: | 1 - 3 limilimithara |

|

5 |

Ho sila botebo | 3 mm (lehlakoreng le le leng) |

|

7 |

Bophara ba phetoho | 1 - 15 m / min |

|

8 |

Ho sebetsa khatello ea moea | 0.7 MPa |

| Sebetsa bophahamo: | 920 - 960 limilimithara | |

|

9 |

Matla a felletseng | Ho potoloha 135 KW / 380V 50Hz 3P |